- - Coal Mining Slurry Pump

- - Slurry Pump

- - Rubber slurry pump

- - Gravel pump

- - High head slurry pump

- - Vertical slurry pump

- - Wear slurry pump

- - Foam pump/Froth Pump

- - Cover Plate Liner,Frame Plate Liner

- - Expeller Ring

- - Front Plate

- - Impeller

- - Volute Liner

- - Medium slurry pump

- - SP vertical slurry pump

- - Light slurry pump

- - Bearing Assembly

- - Rubber parts

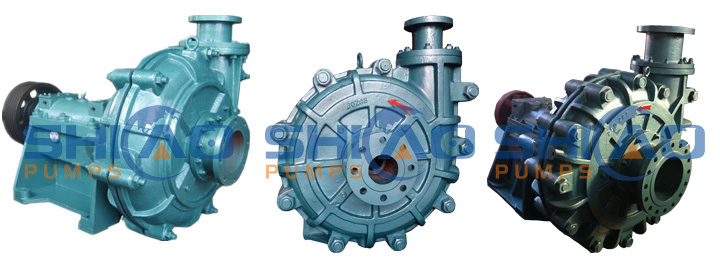

Wear slurry pump

Brief Introduction for Wearable Slurry Pump:

This series of wearable slurry pump can meet the industrial development requirements of thermal power generation, metallurgy, coal mining, and etc. Focus on pumping conditions characteristics of conveying the ash slurry and slag slurry, based on more than decades of slurry pump design and manufacture experiences, we brought and integrated the advanced technology and scientific research achievements from both home and abroad, has successfully developed a newly type generation series of slurry pump that has big flow rate, high pumping head, and can be operated in multi-stage series connection.

Features for MZG Series of Wearable Slurry Pump:

1. Use the current CAD design method, excellent hydraulic performance, high efficiency and low abrasive rate;

2. Wide flowing channel, good anti-blocking performance, and superior NPSH performance;

3. Use associated-impeller+packing combined type sealing and mechanical sealing, to ensure the slurry not to leak out easily.

4. Reliable design ensured that the complete unit greatly been improved the MTBF ( mean time between failures);

5. Use thin oil to lubricating the bearings, reasonable lubrication and cooling system settings, to ensure that the bearing can even work under the low temperature;

6. The flowing-parts use special material of good wear-resistant and corrosion-resistant;

7. After special treatment, the pump can be used for corrosion and erosion working conditions of sea-water ash and sea-water pumping and salt spray and electro-chemical test.

8. Under the allowable voltage range, the pump can be operated in multi-stage series connection, and the max. Working pressure is 3.6Mpa.

Application for MZG Series of Wearable Slurry Pump:

This series of wearable slurry pump has a series of advantages of reasonable structure, high efficiency, reliable operation, easy and convenient maintenance, and etc. It widely applied in metallurgy, thermal power generation, mining, coal mining, chemical, building material and other slurry pumping industry that contains the corrosion and erosion slurry, especially for pumping ash and slag slurry from thermal power plant.

Meanings of the model: MZG80(P)

M---- Wear-resistant high chromium alloy material

80---- Pump Press Out Opening size is 80mm

Z----Wear Slurry Pump

G----High Pumping Head

P----Multi-stage Series connection

MZG Series of Wearable Slurry Pump Performance Parameters:

| Model | Feed-in Opening Size (mm) | Rotate Speed n(r/min) | Clean Water Performance | Shaft Power Pa(kw) | Impeller Diameter(mm) | |||

| Flow Rate Q(L/S) | Pumping Head H(m) | Efficiency η(%) | Net Positive Suction Head (NPSH)(m) | |||||

| MZG65 |

80/65

|

1480

|

15.8-31.7

|

58-61.0

|

48-54

|

3.0-5.5

|

19.7-33.4

|

390

|

|

980

|

10.5-21.0

|

25.4-26.7

|

48-54

|

3.0-5.5

|

5.73-9.69

|

|||

| MZG80 |

100/80

|

1480

|

28.3-56.7

|

87.5-91.6

|

45-64

|

2.7-5.2

|

56.0-75.7

|

490

|

|

980

|

18.8-37.5

|

38.4-40.2

|

45-64

|

2.7-5.2

|

16.3-22.0

|

|||

|

1480

|

25.7-51.5

|

72.2-75.5

|

45-64

|

2.7-5.2

|

42.0-56.7

|

445

|

||

|

980

|

17.1-34.1

|

31.7-33.1

|

45-64

|

2.7-5.2

|

12.2-16.5

|

|||

|

1480

|

23.1-46.2

|

58.3-61.0

|

45-64

|

2.7-5.2

|

30.5-41.1

|

400

|

||

|

980

|

15.3-30.6

|

25.6-26.7

|

45-64

|

2.7-5.2

|

8.8-12.0

|

|||

| MZG100 |

152/100

|

1480

|

58.3-116.7

|

85.1-91.8

|

57-78

|

2.6-6.0

|

91.4-124.9

|

490

|

|

980

|

38.6-77.3

|

37.3-40.3

|

57-78

|

2.6-6.0

|

26.6-36.3

|

|||

|

1480

|

52.5-105.0

|

68.9-74.4

|

57-78

|

2.6-6.0

|

66.7-91.0

|

445

|

||

|

980

|

34.8-69.5

|

30.2-32.6

|

57-78

|

2.6-6.0

|

19.4-26.4

|

|||

|

1480

|

46.7-93.4

|

54.5-58.8

|

57-78

|

2.6-6.0

|

46.9-64.0

|

400

|

||

|

980

|

30.9-61.8

|

23.9-25.8

|

57-78

|

2.6-6.0

|

13.6-18.6

|

|||

| MZG150 |

200/150

|

980

|

100.0-200.0

|

85.2-90.0

|

50.5-74

|

2.7-3.8

|

174.4-226.6

|

740

|

|

740

|

75.6-151.2

|

48.6-51.3

|

50.5-74

|

2.7-3.8

|

75.3-97.7

|

|||

|

980

|

91.2-182.4

|

73.0-77.1

|

50.5-74

|

2.7-3.8

|

135.6-177.1

|

685

|

||

|

740

|

70.2-140.0

|

41.6-44.0

|

50.5-74

|

2.7-3.8

|

59.9-77.7

|

|||

|

980

|

84.6-169.2

|

61.8-65.2

|

50.5-74

|

2.7-3.8

|

107.0-139.0

|

630

|

||

|

740

|

64.8-129.6

|

35.2-37.2

|

50.5-74

|

2.7-3.8

|

46.7-60.7

|

|||

| MZG200 |

250/200

|

980

|

150-300

|

89-94.2

|

63-76

|

2.7-6.7

|

219-343

|

740

|

|

740

|

113.3-227

|

50.7-53.7

|

63-76

|

1.5-3.8

|

94.3-148

|

|||

|

980

|

141.9-283.8

|

79.6-84.3

|

63-76

|

2.4-6

|

186-290

|

700

|

||

|

740

|

107.1-214.3

|

45.4-48.1

|

63-76

|

1.4-3.4

|

80-125

|

|||

|

980

|

129.7-260

|

66.6-70.5

|

63-76

|

2-5

|

142-222

|

640

|

||

|

740

|

98-196

|

38-40.2

|

63-76

|

1.1-2.9

|

61-95.6

|

|||

| MZG250 |

300/250

|

980

|

400

|

84

|

78.2

|

7.3

|

421.2

|

740

|

|

333.3

|

88

|

77

|

5.7

|

373.4

|

||||

|

740

|

302

|

47.9

|

78.2

|

4.2

|

181.4

|

|||

|

251.7

|

50

|

77

|

3.3

|

160.9

|

||||

|

980

|

378.4

|

75.2

|

78.2

|

7.1

|

356.7

|

700

|

||

|

315.3

|

78.7

|

77

|

5.1

|

316

|

||||

|

740

|

285.7

|

42.9

|

78.2

|

4

|

153.7

|

|||

|

238.1

|

44.9

|

77

|

2.9

|

136.1

|

||||

|

980

|

348.6

|

63.8

|

78.2

|

5.5

|

278.8

|

645

|

||

|

290.5

|

66.9

|

77

|

4.3

|

247.4

|

||||

|

740

|

263.2

|

36.4

|

78.2

|

3.1

|

120.1

|

|||

|

219.4

|

38.1

|

77

|

2.5

|

106.4

|

||||

| MZG300 |

350/300

|

980

|

533.3

|

84.3

|

81.2

|

6.9

|

543

|

760

|

|

444.4

|

89.8

|

80

|

5

|

489.1

|

||||

|

740

|

402.7

|

48.1

|

81.2

|

3.9

|

234

|

|||

|

335.6

|

51.2

|

80

|

2.9

|

210.6

|

||||

|

980

|

493.3

|

72.1

|

81.2

|

5.9

|

429.4

|

703

|

||

|

411.1

|

76.8

|

80

|

4.3

|

387

|

||||

|

740

|

372.5

|

41.1

|

81.2

|

3.4

|

184.8

|

|||

|

310.4

|

43.8

|

80

|

2.5

|

166.6

|

||||

|

980

|

453.3

|

60.9

|

81.2

|

5

|

333.3

|

646

|

||

|

377.8

|

64.9

|

80

|

3.6

|

300.5

|

||||

|

740

|

342.3

|

34.7

|

81.2

|

2.9

|

143.4

|

|||

|

285.3

|

37

|

80

|

2.1

|

129.4

|

||||

English

English русский

русский Español

Español العربية

العربية  langue française

langue française